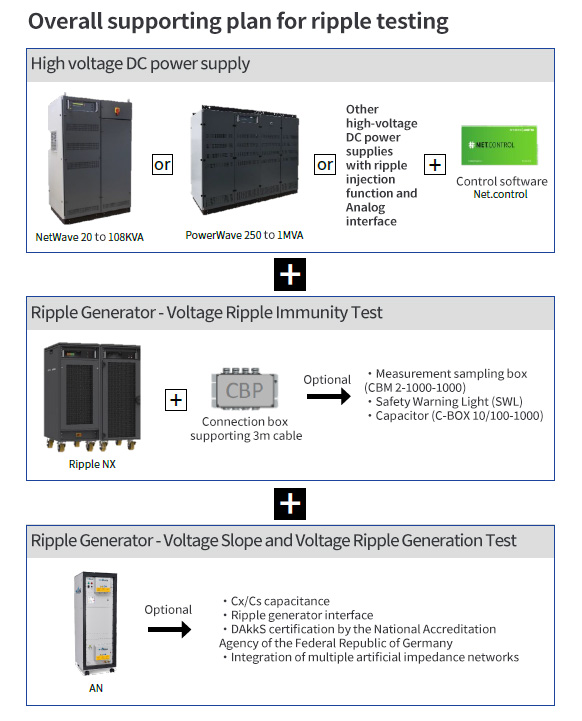

With the pace of automotive electrification, EMC testing of electric vehicles is increasingly becoming an indispensable part of the vehicle development field. Zeer Testing, in collaboration with AMETEK CTS and EN-IMPEDANZ, has established a world's most advanced and cutting-edge solution for conducting immunity and conducted emission testing of EMC high-voltage components.

At present, the most representative testing standard for high-voltage component enterprises is Volkswagen VW80300. Below, we will analyze the corresponding standards and provide corresponding solutions.

VW80300- Electrical Requirements, Test Conditions, and Test Operation Status of Automotive Electrical and Electronic High Voltage Components

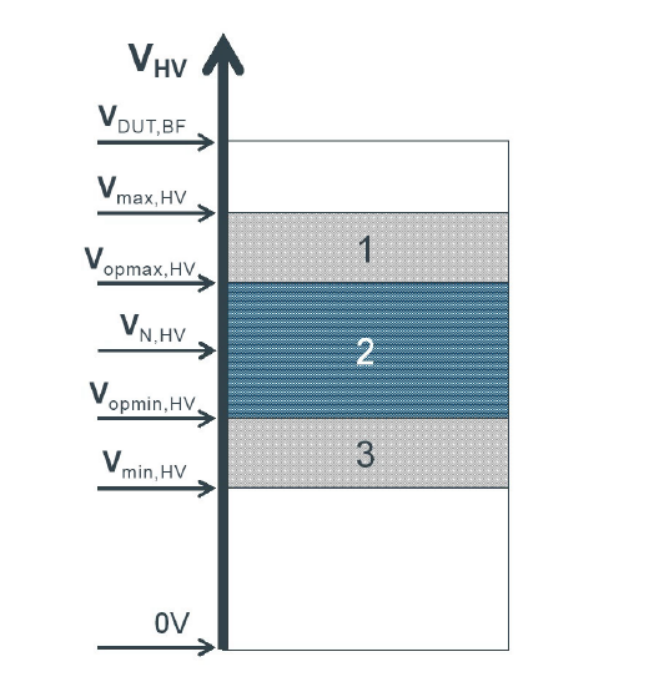

1. Range of high-voltage overvoltage

2. Conventional high-voltage working range

3. High voltage under voltage range

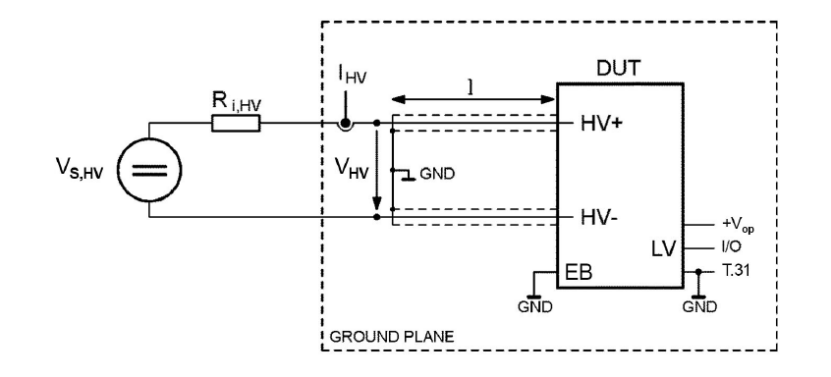

Installation setup diagram

1. For slow events

VS, HV high-voltage voltage source

Ri, internal resistance of HV high-voltage voltage source

The high voltage on the VHV device being tested, for example, measured using a voltage differential probe

IHV high-voltage current measurement, for example, using a clamp current probe

The length of the shielded high-voltage cable on the tested device

Connection between equipotential bonding of EB tested devices

GND ground plane connection

The length I of the shielded high-voltage cable should be at least 200 millimeters. The maximum length is defined by the length of the original high-voltage cable installed in the vehicle.

Shielded high-voltage cables allow a distance of 0 to 100 millimeters above the ground plane.

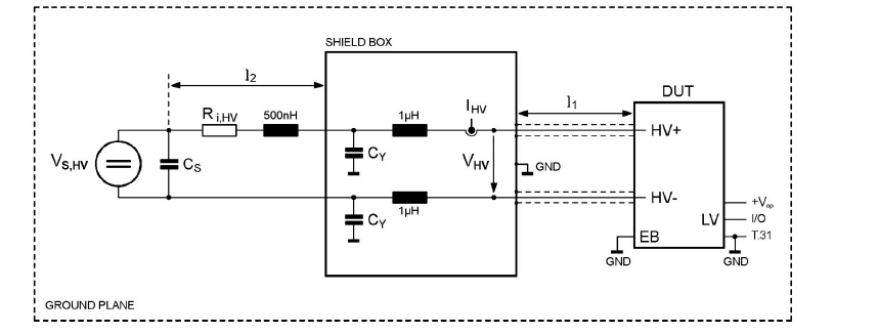

2. For rapid events

VS, HV high-voltage voltage source

Decoupling capacitors connected in parallel between CS and high-voltage voltage sources, 10000 unless otherwise specified μ F

Ri, internal resistance of HV high-voltage voltage source

Y capacitor in CY high-voltage battery pack

The high voltage on the VHV device being tested, for example, measured using a voltage differential probe

IHV high-voltage current measurement, for example, using a clamp current probe

The length of the shielded high-voltage cable on the tested device

The length of high-voltage cables and sub components between the L2 high-voltage voltage source and the shielding area

Connection between equipotential bonding of EB tested devices

GND ground plane connection

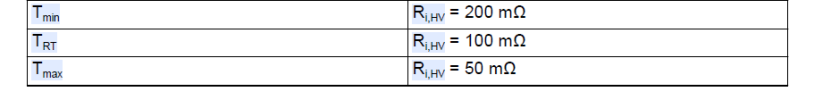

The values of Ri and HV are shown in the table below

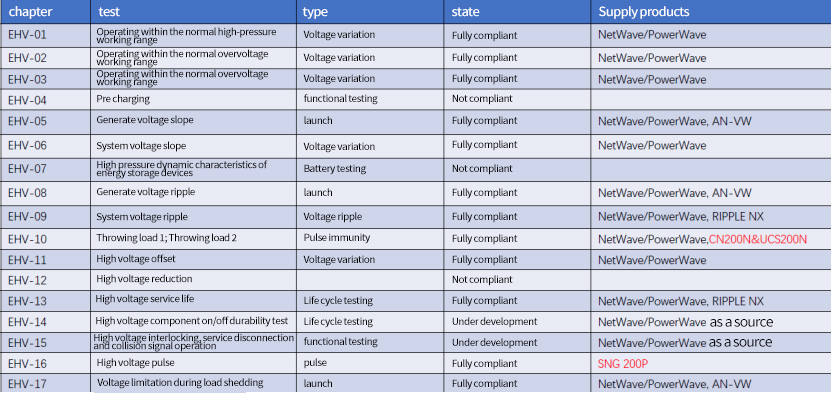

Zeer provides corresponding supporting solutions based on the testing projects in VW80300

Testing standards and corresponding solutions in VW80300

Many tests in VW80300 belong to functional or battery testing and are not covered by Zell's solution. In addition, for the testing requirement of 3000V/ms voltage change required for EHV-10 load shedding 2, Zell uses a micro pulse generator UCN200N to achieve the testing requirement, while for EHV-16 high-voltage pulse testing, it needs to be completed through a switch noise generator SNG200P. Although this equipment does not belong to the Zell testing ripple testing matching scheme, we can still provide it.

For more product information, please contact Chongqing Zeer Technology Co., Ltd

Phone number 18221809217 (same as WeChat)